Table of Contents

Cura Machine settings for BLTouch

Apart from adding the automatic BLTouch calibration before printing, there are many settings in Cura which affect printing quality. Keep in mind that even if BLTouch calibration is configured and executed correctly, printing quality may still be adverse due to other settings.

1. Automatic bed calibration

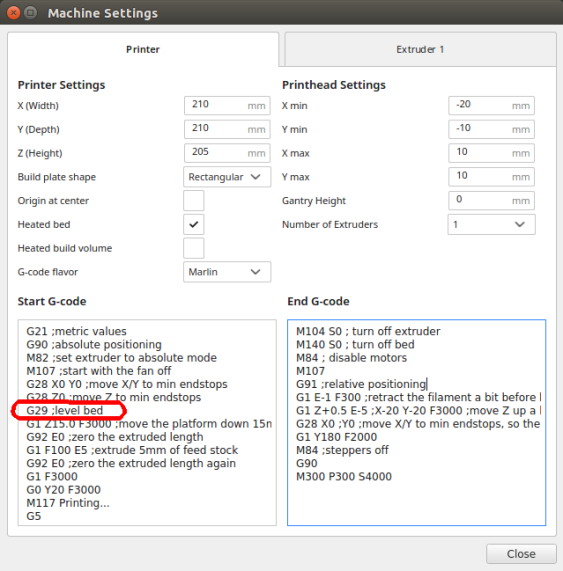

To make sure that when printing, the bed calibration automatically takes place, add G29 under the latest line containing G28 in the Cura machine settings. The following images show where to find and edit the machine settings:

2. Initial feed for sticking layer

Additionally, change the extrude feed stock 2) from 3 into 5: G1 F100 E5

3. Cura 4.4.2 - {speed_travel} bug

In Cura 4.4.2 there is a bug in which the speed_travel variable is defined as mm/min., but interpreted as mm/second. Therefore the printer has a super slow travel speed and is a factor 60 too low. Solve by replacing the {speed_travel} placeholder with the value 3000.

| Start G-Code | End G-Code |

|---|---|

| G21 ;metric values G90 ;absolute positioning M82 ;set extruder to absolute mode M107 ;start with the fan off G28 X0 Y0 ;move X/Y to min endstops G28 Z0 ;move Z to min endstops G29 ;level bed G1 Z15.0 F3000 ;move the platform down 15mm G92 E0 ;zero the extruded length G1 F100 E5 ;extrude 5mm of feed stock G92 E0 ;zero the extruded length again G1 F3000 G0 Y20 F3000 M117 Printing… G5 | M104 S0 ; turn off extruder M140 S0 ; turn off bed M84 ; disable motors M107 G91 ;relative positioning G1 E-1 F300 ;retract filament before lifting nozzle, to release some pressure G1 Z+0.5 E-5 ;X-20 Y-20 F3000 ;move Z up a bit and retract filament even more G28 X0 ;Y0 ;move X/Y to min endstops, so the head is out of the way G1 Y180 F2000 M84 ;steppers off G90 M300 P300 S4000 |

Cura Profile settings

Cura comes per default with settings and profiles for the Anycubic I3 Mega. Even after multiple attempts, it was not possible to get the first layer to stick. So with advice from this page it was possible to get some decent result: A flat equally distributed bottom layer with regular layers on top of that. Also at start the extruder motor had sometimes difficulties in pushing the filament strong enough inside, By reducing the speed, this did not happen again.

The following “0.15mm High” profile (PLA) was created from the default “High 0.1mm” profile:

| Parameter | Default High 0.1mm Profile | High 0.1mm Profile | High 0.15mm Profile | Unit |

|---|---|---|---|---|

| Comment | DOES NOT WORK | WORKS FINE | WORKS FINE | |

| Quality | ||||

| Layer Height | 0.10 | 0.10 | 0.15 | mm |

| Initial Layer Height | 0.10 | 0.10 | 0.10 | mm |

| Line Width | 0.40 | 0.35 | 0.35 | mm |

| ..Wall Line Width | 0.40 | 0.35 | 0.35 | mm |

| ….Outer Wall Line Width | 0.40 | 0.35 | 0.35 | mm |

| ….Inner Wall(s) Line Width | 0.40 | 0.35 | 0.35 | mm |

| ..Top/Bottom Line Width | 0.40 | 0.35 | 0.35 | mm |

| ..Infill Line Width | 0.40 | 0.35 | 0.35 | mm |

| Initial Layer Line Width | 140 | 200 | 200 | % |

| Shell | ||||

| Wall Thickness | 1.2 | 1.2 | 1.2 | mm |

| ..Wall Line Count | 3 | 3 | 3 | |

| Top/Bottom Thickness | 1.2 | 1.2 | 1.2 | mm |

| ..Top Thickness | 1.2 | 1.2 | 1.2 | mm |

| ….Top Layers | 8 | 8 | 8 | |

| ..Bottom Thickness | 1.2 | 1.2 | 1.2 | mm |

| ….Bottom Layers | 8 | 8 | 8 | |

| Optimize Wall Printing Order | ✔ | ✔ | ✔ | |

| Fill Gaps Between Walls | Everywhere | Everywhere | Everywhere | |

| Horizontal Expansion | 0 | 0 | 0 | mm |

| Enable Ironing | ||||

| Infill | ||||

| Infill Density | 25 | 20 | 20 | mm |

| ..Infill Line Distance | 1.4 | 1.75 | 1.75 | mm |

| Infill Pattern | ZigZag | ZigZag | ZigZag | |

| Infill Overlap Percentage | 15 | 15 | 15 | % |

| Infill Layer Thickness | 0.15 | 0.15 | 0.15 | mm |

| Gradual Infill Steps | 0 | 0 | 0 | |

| Material | ||||

| Printing Temperature | 200 | 195 | 195 | ºC |

| Printing Temperature Initial Layer | 0 | 0 | 0 | ºC |

| Initial Printing Temperature | 190 | 195 | 195 | ºC |

| Final Printing Temperature | 185 | 180 | 180 | ºC |

| Build Plate Temperature | 60 | 60 | 60 | ºC |

| Build Plate Temperature Initial Layer | 60 | 60 | 60 | ºC |

| Enable Retraction | ✔ | ✔ | ✔ | |

| Retract at Layer Change | ||||

| Retraction Distance | 6 | 6 | 6 | mm |

| Retraction Speed | 40 | 40 | 40 | mm/s |

| Speed | ||||

| Print Speed | 50 | 40 | 40 | mm/s |

| ..Infill Speed | 50 | 40 | 40 | mm/s |

| ..Wall Speed | 50 | 40 | 40 | mm/s |

| ….Outer Wall Speed | 50 | 40 | 40 | mm/s |

| ….Inner Wall Speed | 50 | 40 | 40 | mm/s |

| ..Top Bottom Speed | 20 | 16 | 16 | mm/s |

| ..Support Speed | 30 | 30 | 30 | mm/s |

| Travel Speed | 50 | 50 | 50 | mm/s |

| Initial Layer Speed | 25.0 | 10.0 | 10.0 | mm/s |

| Skirt/Brim Speed | 40 | 40 | 40 | mm/s |

| Enable Acceleration Control | ✔ | ✔ | ✔ | |

| Enable Jerk Control | ✔ | ✔ | ✔ | |

| Travel, Cooling, Support, Build Plate Adhesion, Dual Extrusion, Special Modes, Experimental | ||||

| All Default values | ||||